pvc laminated gypsum ceiling board

Links

-

You can also be sure the material will be allowed within your region or country if you are importing from a different country.

- In conclusion, door rollers for sliding doors are a vital component in creating a functional and attractive sliding door system. By providing support, reducing friction, and improving the overall performance of the door, door rollers play a crucial role in ensuring that sliding doors operate smoothly and efficiently for years to come. Proper maintenance and care of door rollers will help extend the life of the door and keep it looking and functioning at its best.

- The functionality of the sliding door rollers is not just confined to convenience; it significantly impacts the door's security. Well-functioning rollers ensure that the door fits snugly into its track, minimizing any potential gaps that could be exploited by would-be intruders. Moreover, a door with sturdy rollers will resist forced entry attempts, thereby enhancing the overall security of the property.

Its high tensile strength makes it ideal for load-bearing applications like bridges and building supports Its high tensile strength makes it ideal for load-bearing applications like bridges and building supports

Its high tensile strength makes it ideal for load-bearing applications like bridges and building supports Its high tensile strength makes it ideal for load-bearing applications like bridges and building supports wrought iron. Moreover, its resistance to rust makes it perfect for outdoor use, where it can withstand the elements without losing its integrity.

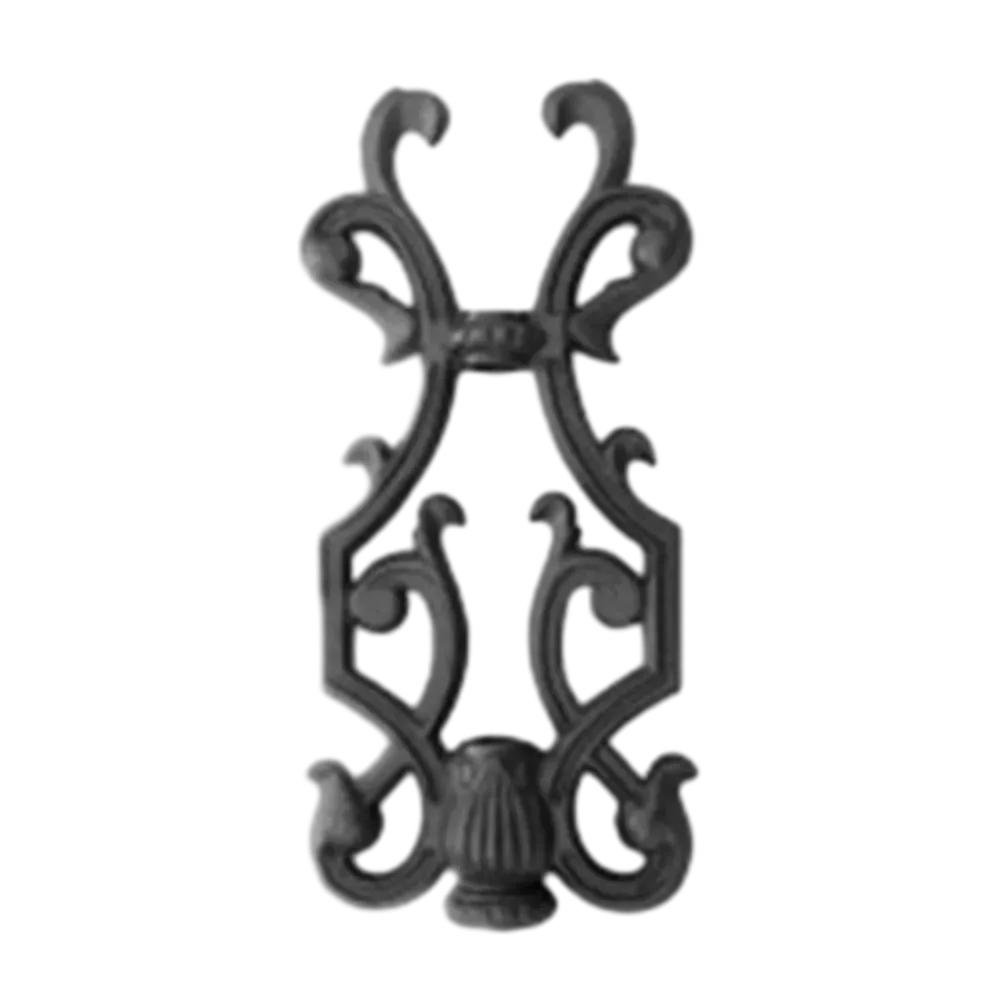

wrought iron. Moreover, its resistance to rust makes it perfect for outdoor use, where it can withstand the elements without losing its integrity. The Beauty of Okrasná Liatina A Journey into Decorative Cast Iron

BSAA offers excellent corrosion protection and paint adhesion features compared to chromic-acid anodize. It is suitable for tight tolerances, bonding, corrosion protection, and it is non-conductive.

Aluminium Windows Profiles

Finally, in order to build a shed with an aluminium frame profile you need to ensure that you get a good set of plans. These will give you everything that you need so that you can build the shed with minimal hassle. Remember, even the smallest shed can look impressive if you choose the right plan. However, you should always ensure that it is the correct plan that you have purchased. This will make sure that you do not waste any materials and so that you can concentrate on the building process.

Why settle for average when you can opt for extraordinary? we believe that your property deserves nothing less than the best, which is why we specialize in crafting high-quality wrought iron fences in Austin, TX tailored to your specific needs.

Maintenance Requirements for Cast Iron vs. Wrought Iron Fencing

As you can see, maintaining an iron fence isn’t impossible. It takes some time, skill, and attention, but hopefully, we’ve helped you feel more confident about tackling the job. An iron fence can make a beautiful addition to your property and is the sturdy choice for keeping your assets protected from outsiders, but you also have to keep the fence itself safe from outside elements. Vigilance is key to keeping your iron fence strong and appealing for ages to come.

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box

The versatility of stainless steel boxes with locks is another compelling reason to consider them. They are not limited to a specific use; instead, they can serve various purposes across different contexts. In office environments, these boxes can securely store confidential files, protecting sensitive information from prying eyes. For individuals, they can serve as safes for important documents, jewelry, cash, or heirlooms. Additionally, in industrial settings, stainless steel boxes can safeguard tools and equipment, ensuring that everything is organized and protected against theft or damage.

Custom Craftsmanship. If you want to genuine one of a kind fence, wrought iron is the right choice. It can be heated and shaped with great levels of detail and it the quality of work will differentiate your fence from all the rest.

As a supplier of aluminum door and window profiles, we know very well that customers have higher and higher expectations for the appearance of doors and windows. Therefore,Aluminum has also invested a lot of technology in the surface treatment of aluminum profiles to meet customers' needs. So what surface treatments are often used for aluminum door and window profiles? Usually include matte, multi-color surface treatment, electrophoretic, anodizing, polishing, and other processes.

Anodizing

Anodizing can overcome defects in aluminum alloy surface hardness and wear resistance. Anodized aluminum profile, anti-static, easy to clean without dust collection, has excellent heat dissipation. Beautiful appearance, uniform color, no fading. It can also improve the bonding force between the organic coating and the inorganic covering layer. Anodizing is also the door and window surface treatment technology most favored by Aluminum customers.

Powder coating

Powder coating uses electrostatic coating equipment to spray powder coating onto the profile surface. Powder-coated aluminum profiles are available in various colors, with a low probability of color difference and good corrosion resistance. We have our vertical powder coating equipment workshop that supports aluminum profiles of any length. If you want to know more, you can contact us.

Electrophoretic spraying

Electrophoretic paint film has full, uniform, smooth, and smooth coating advantages. The electrophoretic coating is highly resistant to corrosion and weathering. It has a more decorative effect than spray paint or powder coating, which is very popular among customers.

Matte treatment

The main function is surface cleaning. Sandblasting of aluminum alloy doors and windows before painting (painting or plastic spraying) can increase surface roughness and improve adhesion to a certain extent. Still, the contribution is limited, which is better than the pre-treatment of chemical paint. The matte aluminum profile avoids the defect that the bright aluminum alloy profile will cause light interference under certain circumstances and conditions in architectural decoration. Its surface is as delicate and soft as brocade, which is very popular among customers.

Wood Grain

Wood grain transfer is a surface treatment technology that reproduces various wood grain textures on the surface of aluminum profiles. Wood grain transfer printing has excellent anti-aging, fading, corrosion resistance, and weather resistance and fully displays the beautiful wood grain texture, which is also very popular among customers.

Aluminum profile surface treatment is one of the important links in producing aluminum alloy doors and windows. Good surface treatment greatly affects the corrosion resistance, weather resistance, and service life of aluminum alloy doors and windows. With the continuous advancement of technology, Aluminum can provide aluminum profiles with higher quality and more favorable prices for door and window suppliers.

roller wheels for screen doors. Roller Wheels These are typically sold in pairs and should be selected based on the size of your screen door frame.

roller wheels for screen doors. Roller Wheels These are typically sold in pairs and should be selected based on the size of your screen door frame.